Killing process

The killing process is the first process in the poultry processing and consists of hanging,

electric stunning, bloodletting, scalding, and defeathering processes.The by-products

(blood, feathers, hair, feet, gizzard and etc.) produced in this process are discharged through

processing equipment after transport.

-

|

|

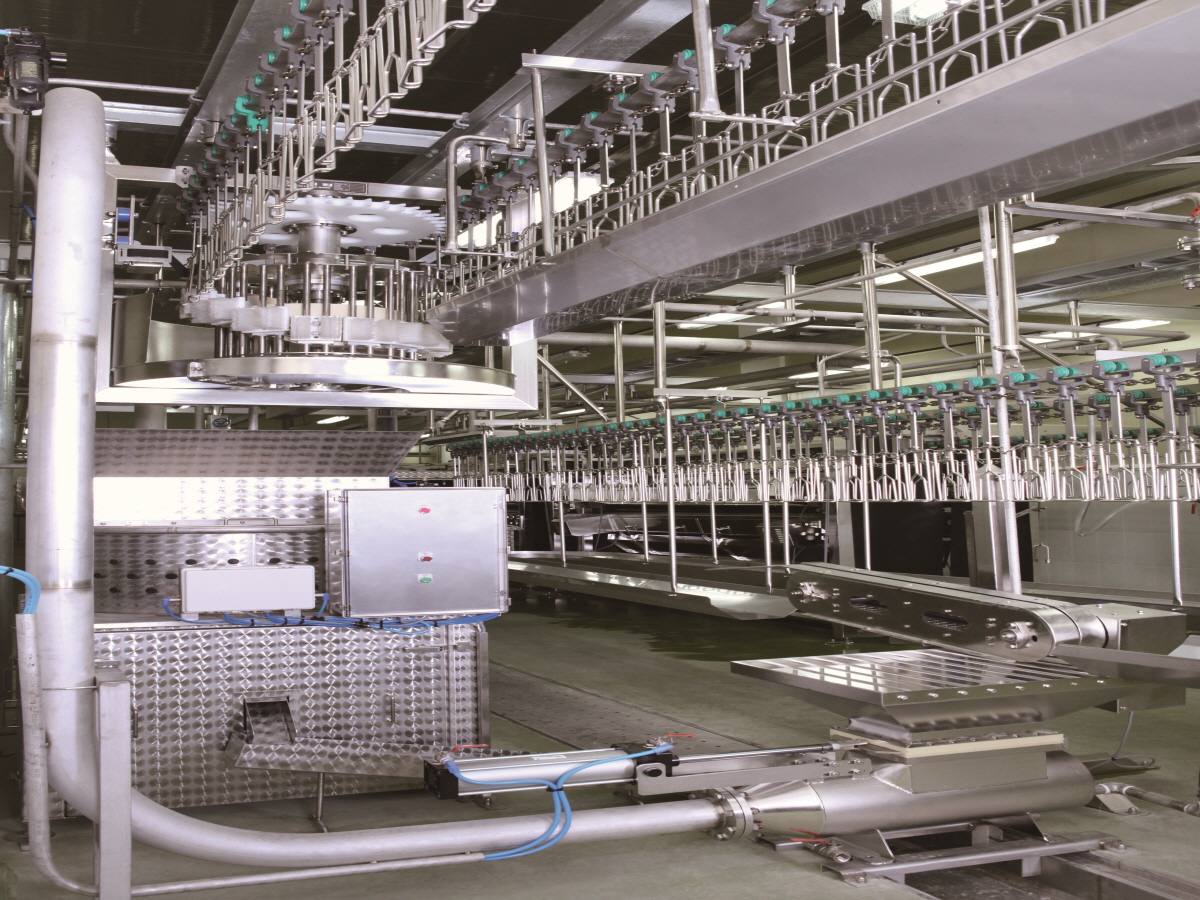

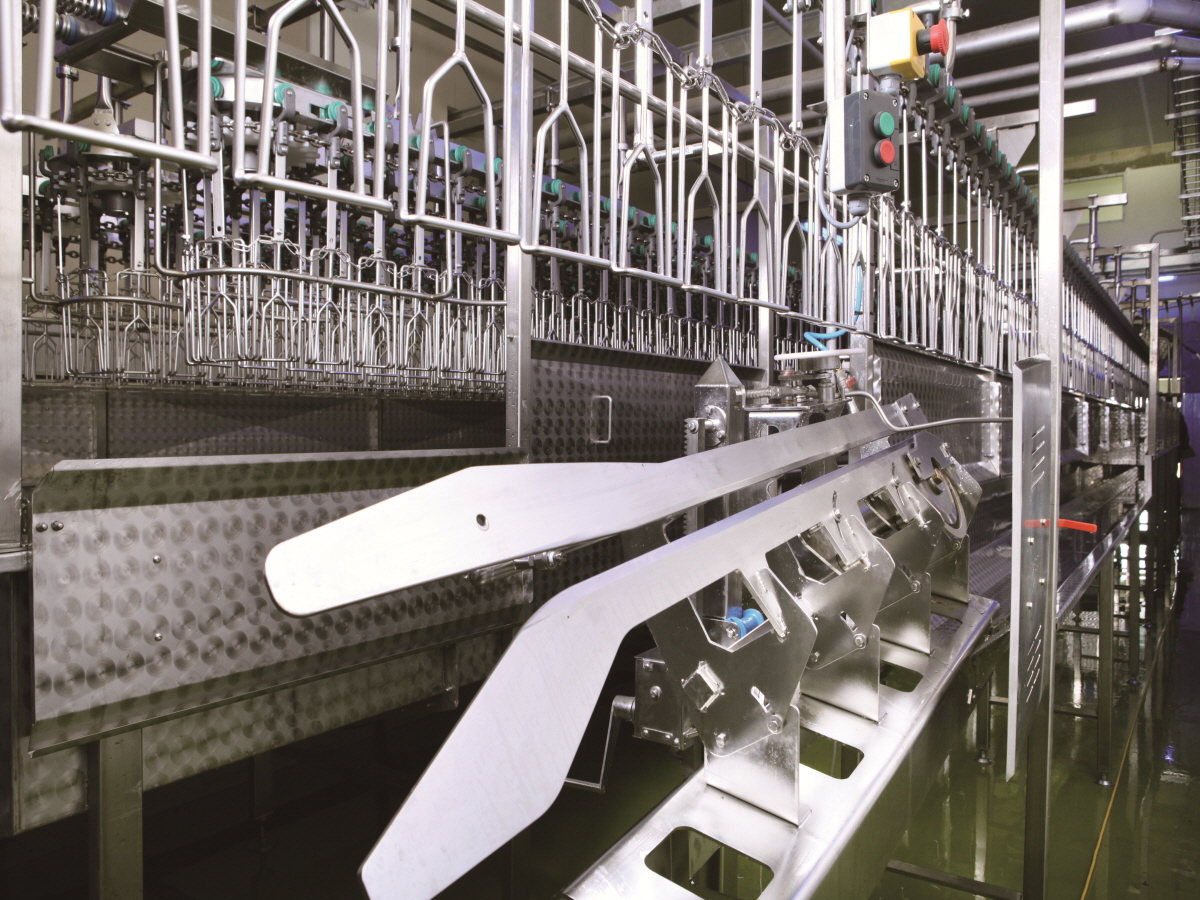

1. Turn table

- In order to effectively hanging, a system secures working space and rotates the live birds while hanging

|

|

|

-

|

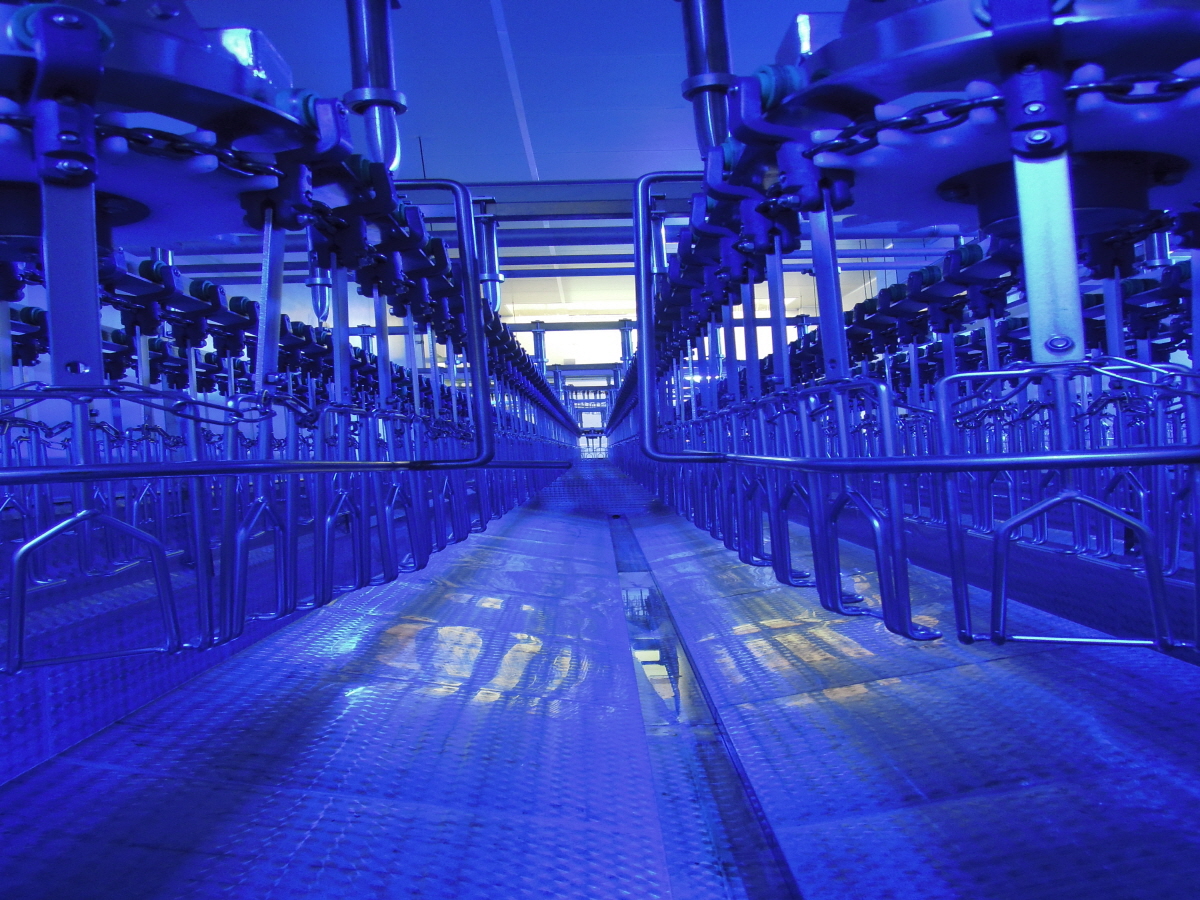

2. Electric stunning

- It is a low-voltage, high-frequency control method that maintains a state of fainting in which the heart does not stop during electric stunning. - Frequency, voltage, and height can be adjusted according to poultry’s condition.

|

|

|

|

-

|

|

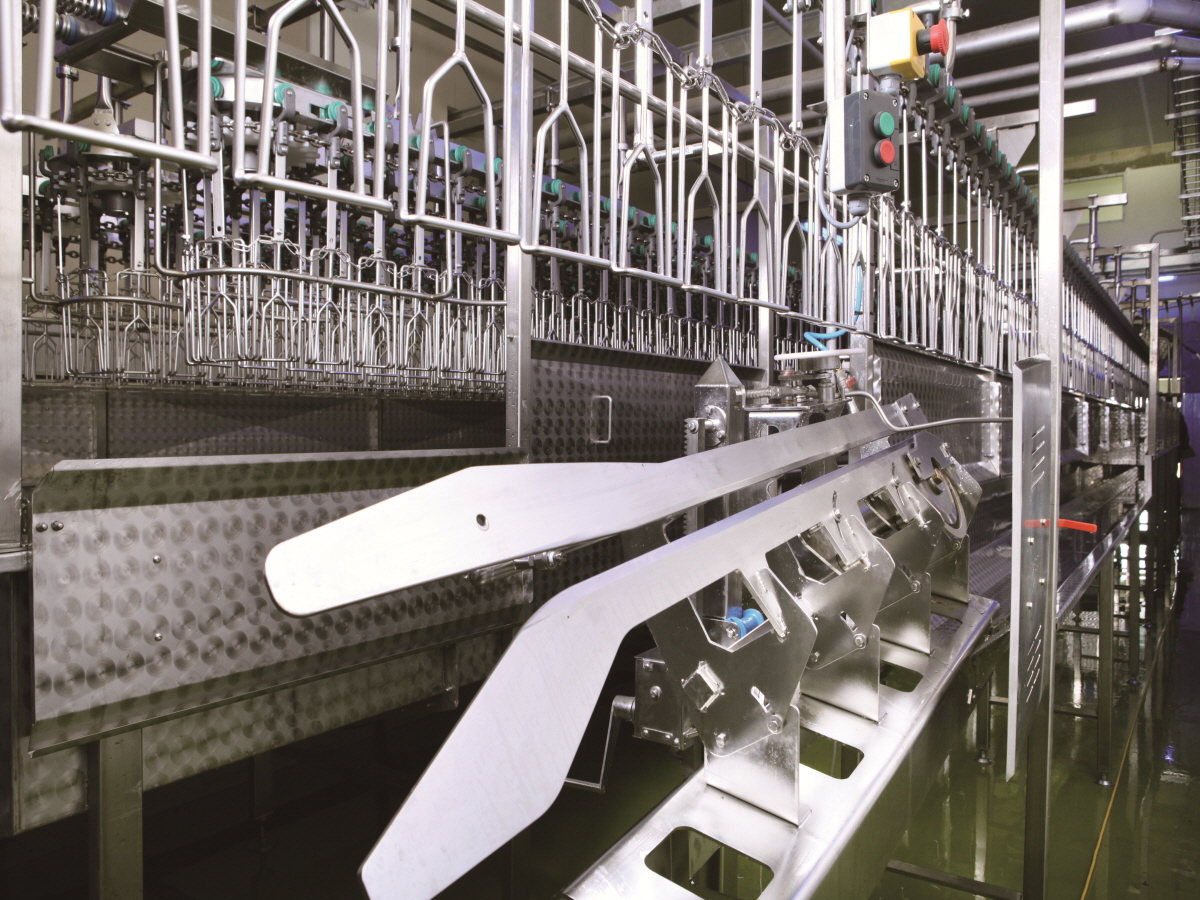

3. Carotid artery cutter / Killing Machine

- The poultry guidance method prevents wing breakage upon entry and accurately cuts the carotid artery. - Easy to adjust height regardless of the size of the poultry

|

|

|

-

|

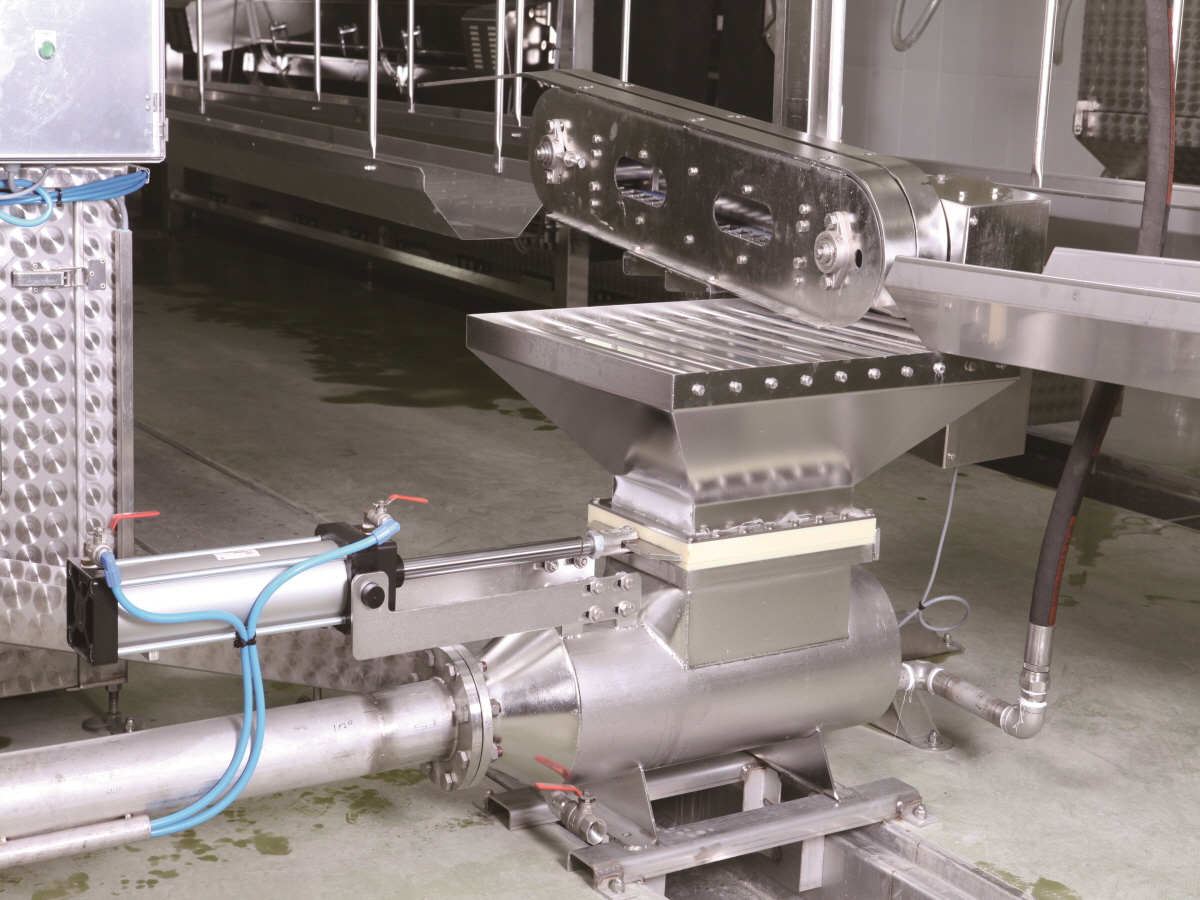

4. Bleeding Trough / Blood collection tank

-A scattering cover is attached to prevent blood from scattering. - The bottom drainage channel is sloped for smooth blood discharge.

|

|

|

|

-

|

|

5. Scalder

- The impeller and air blower are used in combination to effectively rotate the water circulation within the steamer to prevent temperature deviation. - The stirring impeller causes the hot water in the scalding water to swirl, preventing the conductor from floating and maximizing the scalding effect. - It is manufactured to enable temperature control in each section, and a digital temperature indicator is installed in each section to display and control the temperature in real time.

|

|

|

-

|

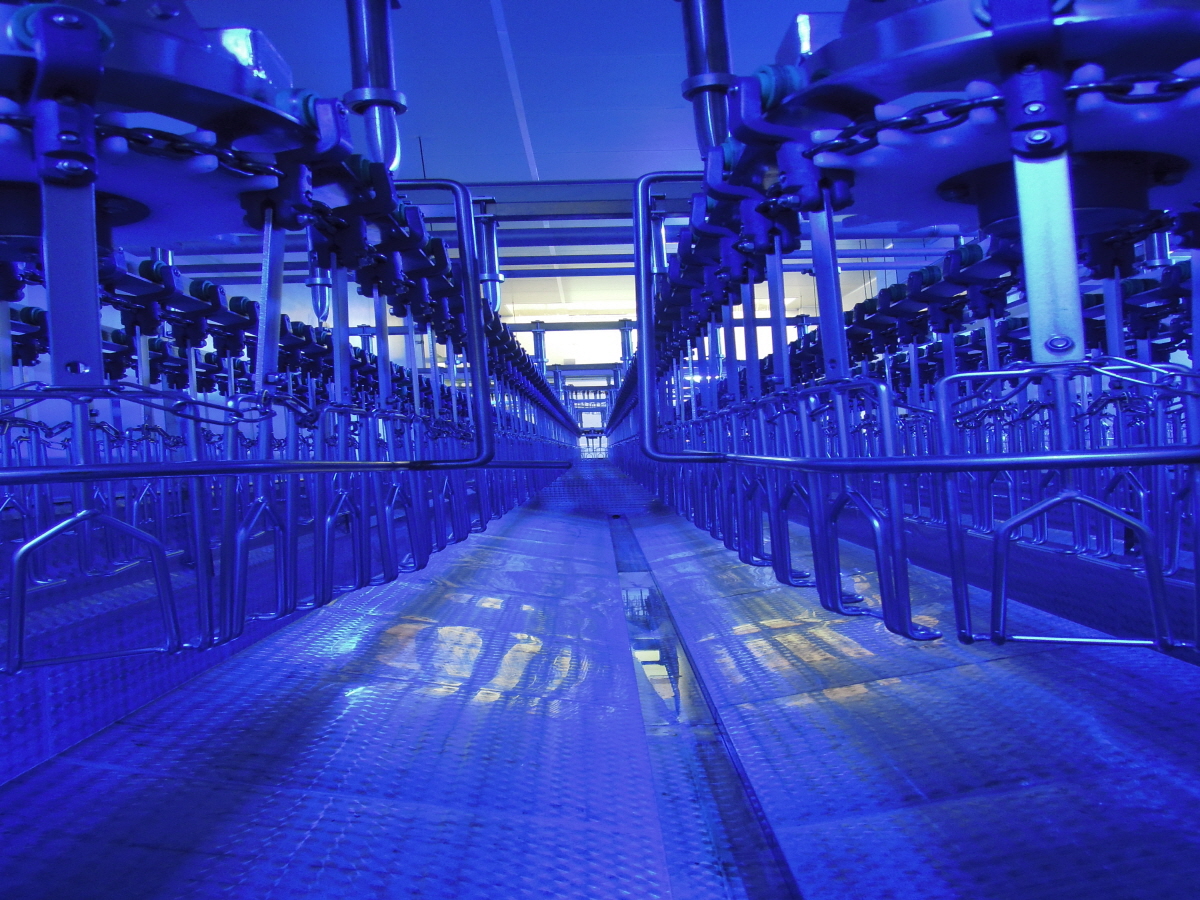

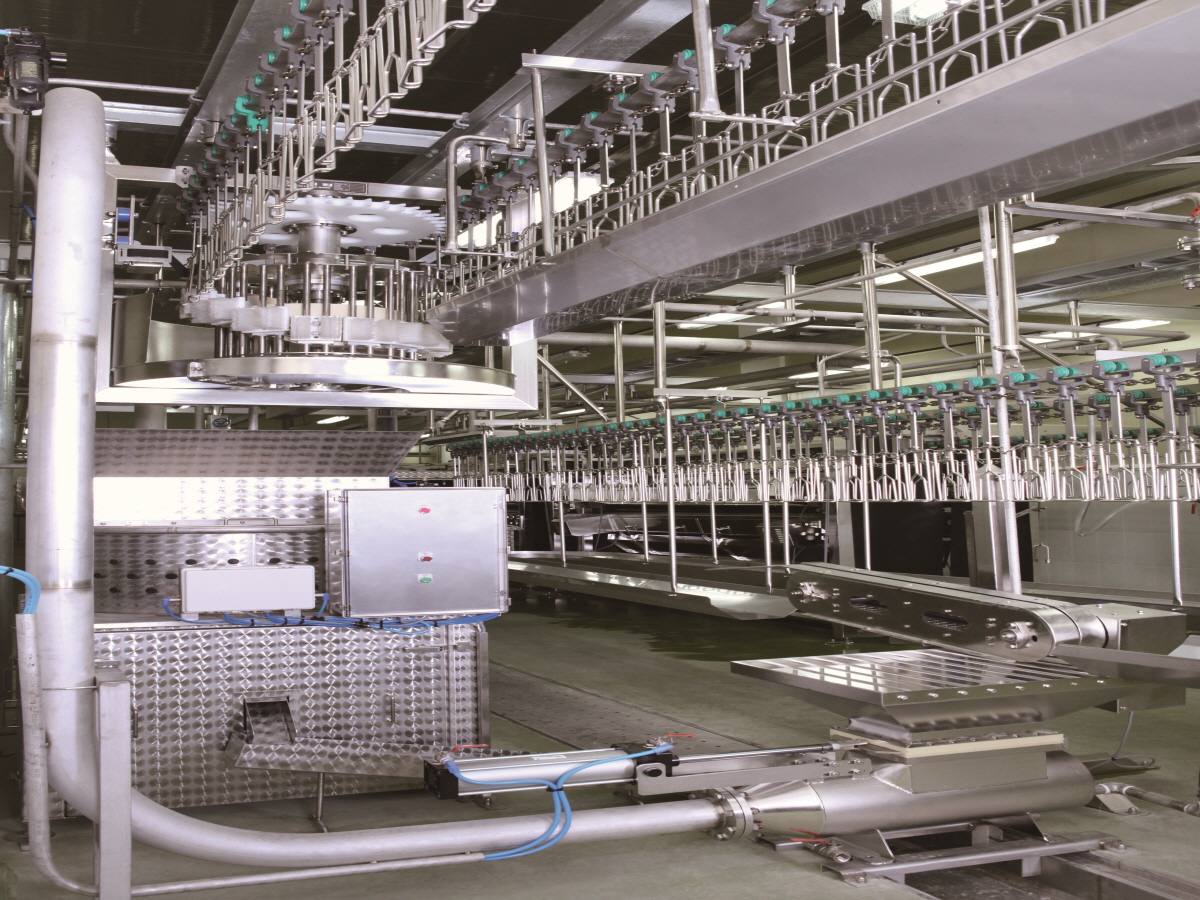

6. Plucker

- By reducing the size of the disc plate and assembling the finger mounting direction diagonally, the blind spot of the poultry during de-feathering is minimized to maximize de-feathering efficiency and at the same time, the impact on the poultry carcass is minimized. - Easy to adjust each row and height angle, so there are no blind spots for de-feathering - Minimizes impact, reduces pore rupture and epidermal damage, and minimizes breakage of poultry carcass

|

|

|

|

-

|

|

7. Head puller

- A puller type that removes hair through a guide and a type that cuts with a blade. -Manufactured to ensure consistent entry of poultry carcass by using a guide conveyor upon entry.

|

|

|

-

|

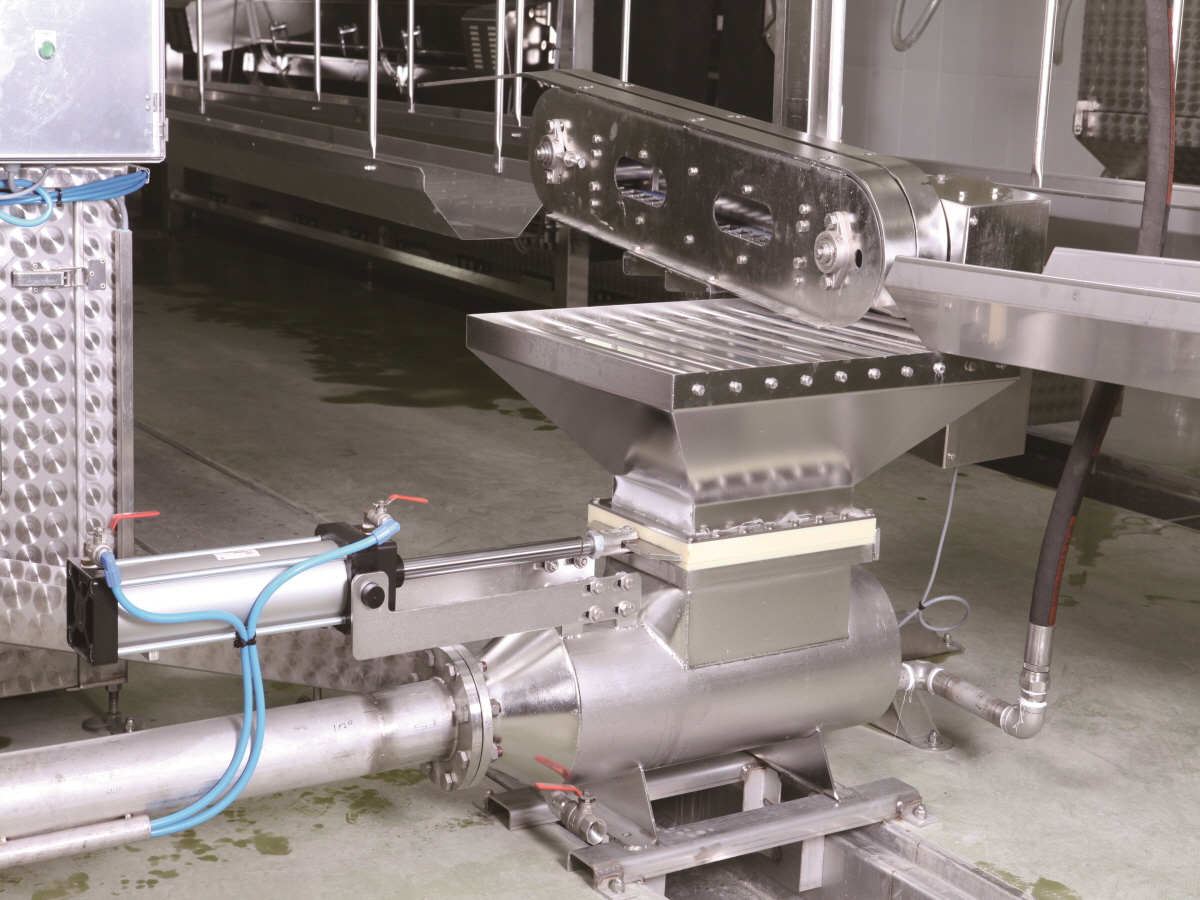

8. Foot dropper

-MC cam-based operation minimizes load even when operating at high speeds - For stable foot removal, a shackle fixing device is attached to ensure smooth foot removal.

|

|

|

|

-

|

|

9. Foot peeler / Round plucker

- Efficient removal of poultry feet by rotating fingers - Stripping time and rotation speed can be adjusted, allowing individual settings depending on the breed of poultry carcass

|

|

|