Evisceration process

A process that removes internal organs from poultry carcass and automatically transfers depilated poultry

carcass to remove by-products and wash them.

-

|

|

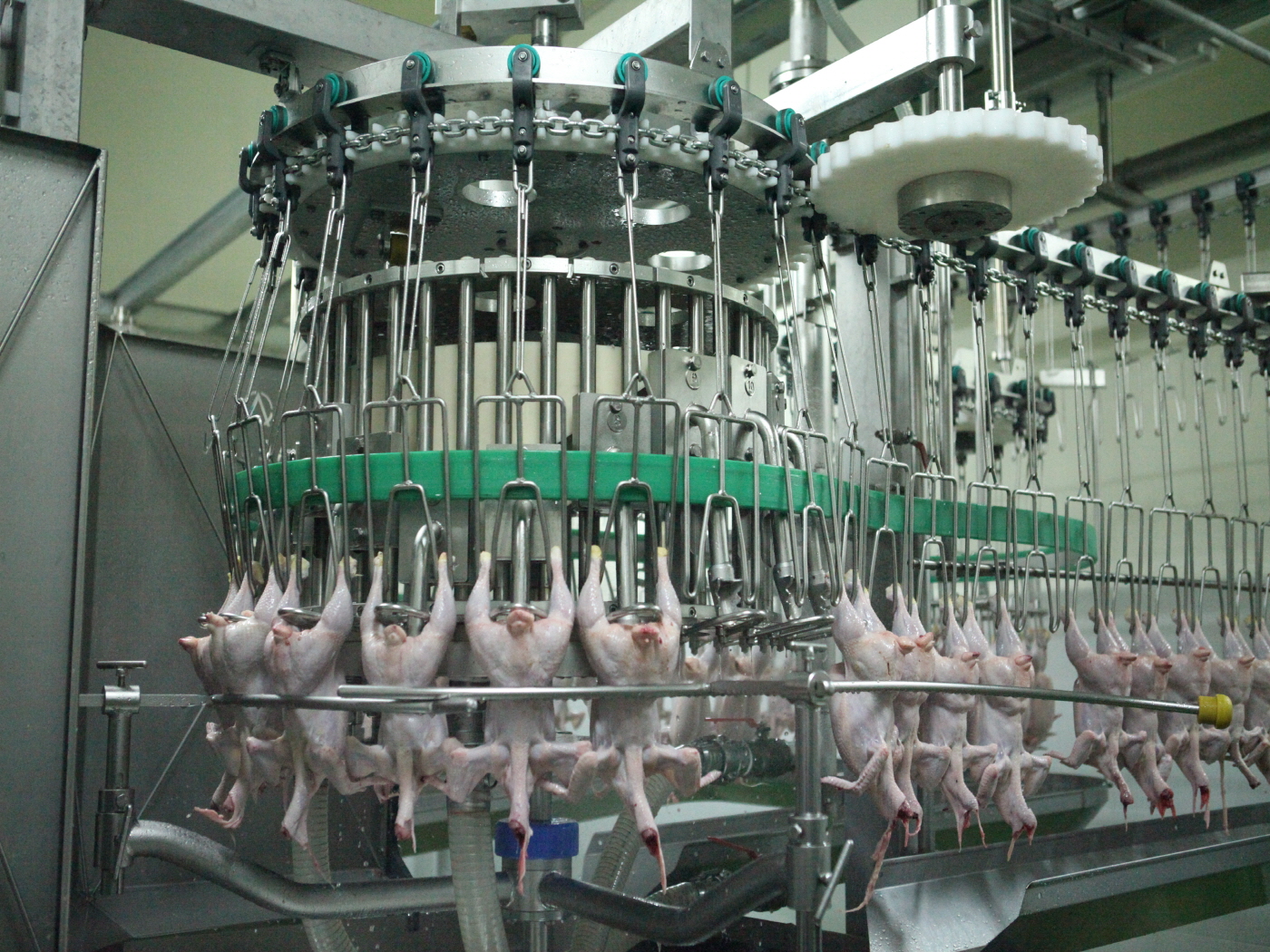

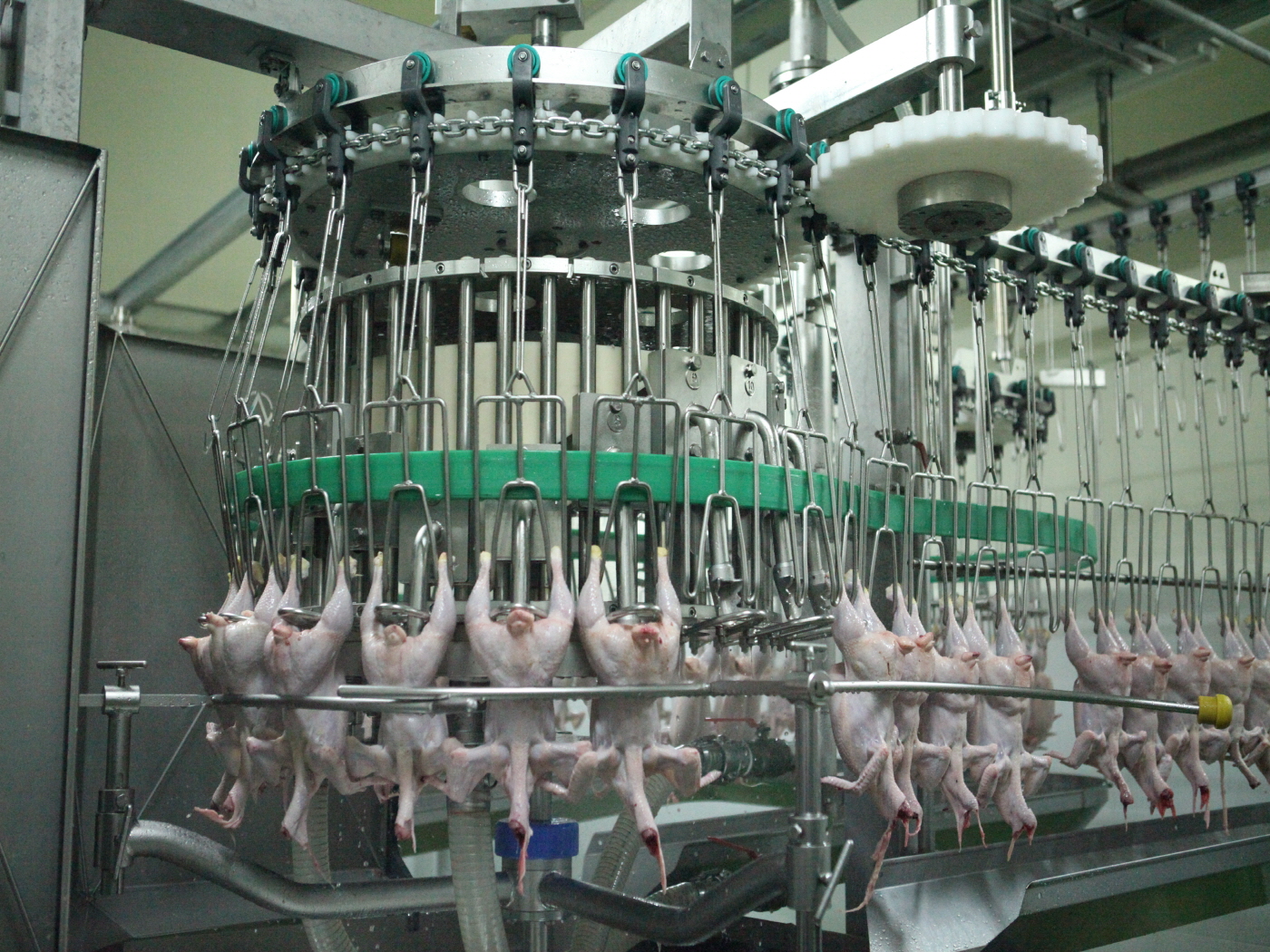

1. Automatic transfer (Re-hanging) machine

- Maximizes handover rate by adopting a high-precision encoder method - Simplified machinery ensures no breakdowns and is easy to maintain - High tolerance even when the size of poultry carcass is different - The foot cutter blade is made of durable material

|

|

|

-

|

2. Vent cutting machine

-The probe accurately enters the reference point in the center of the unknown line, minimizing errors. - The rotating circular blade cuts the vent accurately and then pulls up a certain section to hang it out of the poultry carcass - The screw circular blade has excellent durability as it uses a specially heat-treated blade. - Automatically cleans the vent blade after venting to prevent cross-contamination. - The vent blade is screw-type, can be assembled and disassembled, and is easy to replace.

|

|

|

|

-

|

|

3. Opening machine

- Accurately sets the reference point during opening to reduce errors - A protection ball is attached to prevent organ’s damage during opening - Uses stainless steel blades that do not rust

|

|

|

-

|

4. Evisceration machine

- Effective evisceration by accurately determining the reference point of poultry carcass during evisceration - During evisceration, the spoon is designed to fit the structure of the poultry carcass, reducing damages of inside of poultry carcass. - Increasing inclusiveness according to differences in poultry carcass

|

|

|

|

-

|

|

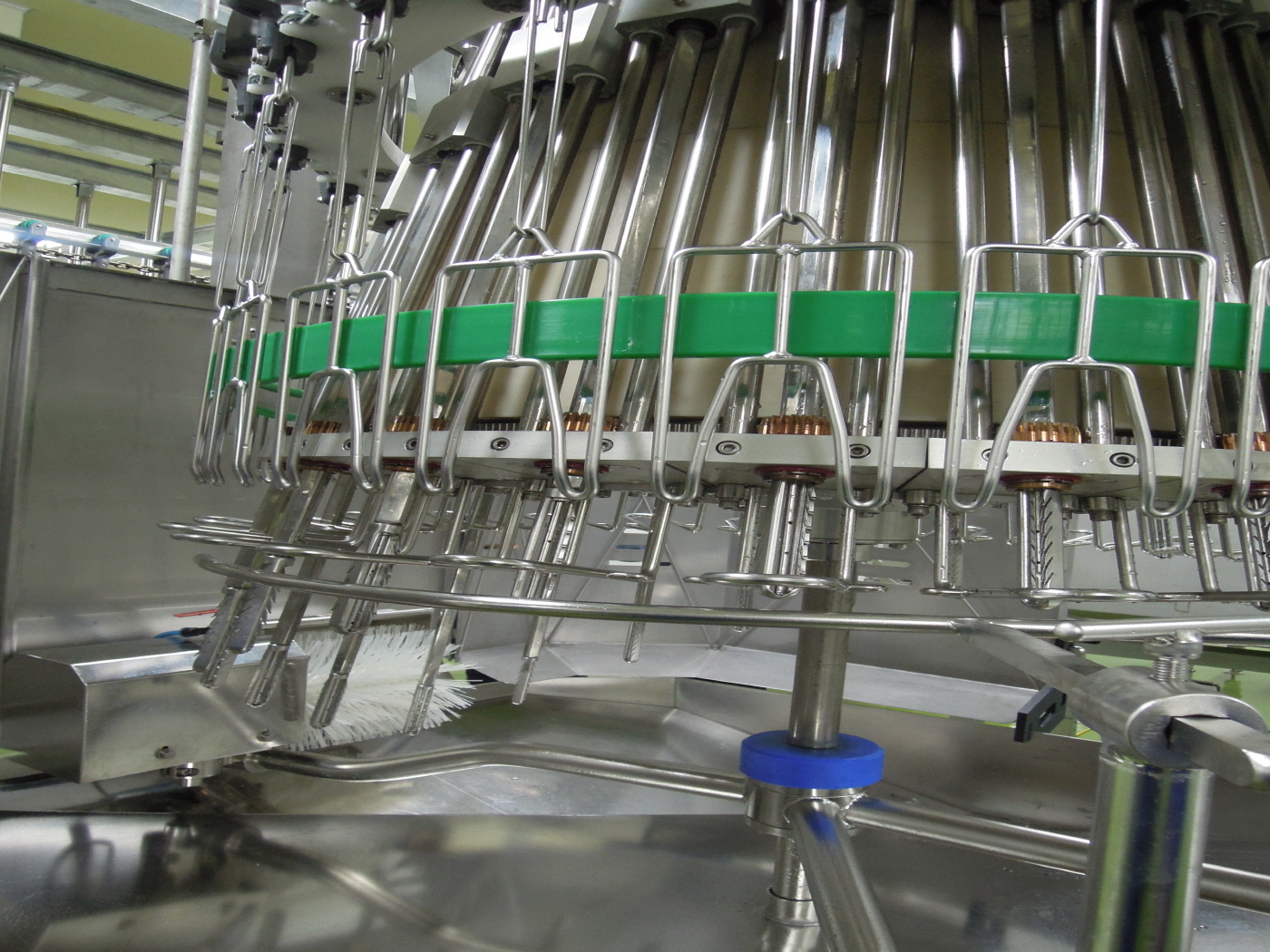

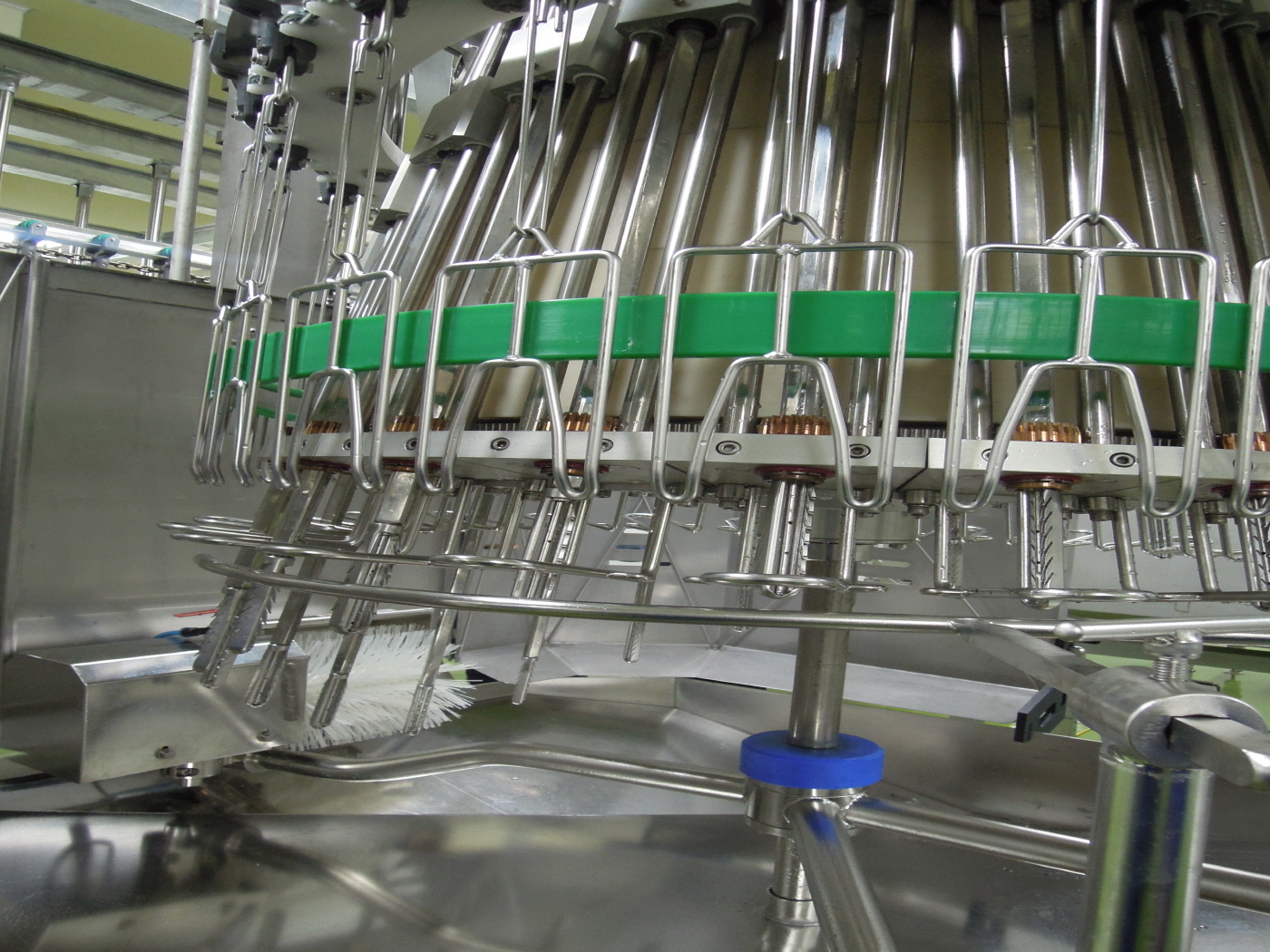

5. Cropping machine

- As the spindle rotates past the abdominal fat, it effectively removes the trachea, esophagus, and crop. - The separated trachea, esophagus, and crop are separated from the spindle by a rotating brush. - The spindle is designed as a prefabricated structure, making it easy to replace. - Excellent effectiveness as cleaning water is sprayed inside the spindle

|

|

|

-

|

6. Final inspection machine

- Effectively removes lungs and debris remaining in the abdominal cavity - Automatically cleans the vacuum suction unit to prevent cross-contamination -Easy to adjust water usage, replace parts, and maintain

|

|

|

|

-

|

|

7. Inside and out side washing machine

- Water usage is reduced as the inner washing water is sprayed for each unit. - Valves are installed for each part to save water - With the probe installed, there is no damage to the conductor and the washing water is discharged well.

|

|

|

-

|

8. By-product process

- Equipment that automatically transports and cools by-products from the evisceration process, removes poultry feet, etc. to maintain the freshness of the by-products and transports them to the desired location.

|

|

|

|

-

|

|

9. Electrical panel

- This is an integrated management system that controls all aspects of the slaughtering process. Using PLC and TOUCH, you can check the operation status of the machine and display all error messages, allowing you to manage the machine efficiently.

|

|

|